Ever stepped into a nicely air-conditioned building on a hot Indian summer afternoon and experienced that instant comfort? Or noticed the steam coming off factory buildings, a quiet testament to their essential cooling systems in action. Behind all those nice comforts and essential functions is a fundamental challenge: heat management. Where India’s climate is so diverse and at times so hot, robust cooling is not an indulgence but the key to efficiency and productivity.

If you must cool industrial operations, corporate campuses, or computer systems critical to your mission, two technologies leap to mind first: chiller plants and cooling towers. But which do you employ for your specific needs? Let’s analyse these life-critical cooling technologies, their benefits, and what they mean to your business.

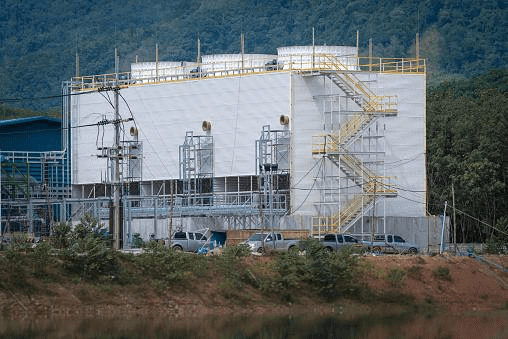

Cooling Towers: The Workhorses of Heat Rejection

Let’s begin with cooling towers. These are usually what come to mind when industrial cooling is at issue – those enormous towers one happens upon next to factories or electricity stations.

What they are & How they work: A cooling tower is a mechanical heat exchanger that employs the evaporative cooling of water in order to cool a process fluid. Hot water from your operation (such as an HVAC system condenser or manufacturing process) is pumped to the roof of the tower, drips over “fill media,” and then huge fans draw or blow air through. When a little water evaporates, it takes a gigantic amount of heat out of the balance of the water and has it recycled. It’s an open system, very efficient at dissipating lots of waste heat. Did you know that the evaporation of just one pound of water will dissipate about 1,000 BTUs of heat? That’s pretty impressive cooling capacity!

Key Benefits:

- Energy Efficiency: In rejecting huge amounts of heat, cooling towers tend to be more energy-efficient to run than chillers, particularly in dry weather.

- Cost-Effective: They tend to have a lower initial capital investment for bulk heat rejection requirements.

- Plain Components: A standard cooling tower has a building, fill media (to increase water-air contact), a fan, drift eliminators (to reduce water loss), and a cold-water basin. Being well-acquainted with these cooling tower components should make you amazed at their innovation.

Things to Consider:

- Water Usage: As a result of evaporation, they do use water. This is something to consider in water-scarce areas.

- Maintenance: Since they are open systems, they undergo routine maintenance to prevent conditions such as scale deposits, algae, and even potential biological growth.

Should you be perusing the various types of cooling towers that exist and how they could be designed customarily for specific industrial applications, you may learn more about our cooling tower solutions page.

Chillers: Precision Cooling for Controlled Environments

And then, naturally, there are chiller plants. These typically appear on commercial buildings for specific air conditioning or industrial processes that require highly specific, and normally colder, temperature management.

What they are & How they work: A chiller plant is similar to an enormous refrigerator. It utilises a refrigeration cycle to transfer heat from a liquid (often water or water/glycol solution). The cooled liquid is circulated around a system in an attempt to harvest heat from air or equipment. It’s a closed-loop chilled water system, so not open to the outside air.

Key Benefits:

- Accuracy Temperature Control: Chillers are excellent in providing exceptionally accurate and low temperatures, which are necessary for sensitive process manufacturing, data centres, or accurate climate control in a facility.

- Closed-Loop System: Less water loss by evaporation since the chilled water system is closed-looped.

- Flexibility: They may be air-cooled (rejected to air directly) or water-cooled (utilising a cooling tower to reject the chiller condenser heat).

Things to Consider:

- Energy Consumption: Chillers would be more energy-intensive than cooling towers under high heat loads.

- Initial Purchase Cost: The Initial purchase cost of a chiller plant is higher.

- Refrigerant Management: They involve refrigerants, which are handled with care and require frequent inspection.

Cooling Towers Vs. Chillers: Making the Right Choice for Your Business

So, the question: which one do I use? It’s really more a question of getting the “right fit” for your particular application and your local conditions, and not that one is always “better.”

- Application Focus: Need to shed lots of heat off of processes that don’t require super-cold temperatures? A cooling tower is probably your choice. Need low, precise temperatures for speciality machinery or pleasant air conditioning? A chiller plant is your solution.

- Climate Conditions: Cooling towers work efficiently in dry climates based on evaporative cooling. In extremely humid climates, their efficiency decreases. Chillers are less prone to ambient humidity.

- Costs: Cooling towers consume less electricity to operate but need water. Chillers use more electricity but conserve water.

- Integration: Most manufacturing facilities indeed use both. The precision cooling comes from a chiller plant, and then a cooling tower effectively rejects the heat of the chiller condenser to the air. Both mass heat rejection and accurate control are supplied with this blend.

Conclusion: Partnering for Optimal Cooling Solutions

Selecting the best industrial cooling system – a single cooling tower, a tailor-made chiller plant, or a smart combination – is a business-strategic necessity. It has a very immediate impact on your operating effectiveness, energy consumption, and overall long-term sustainability. It’s not a question of equipment choice, but of selecting a solution that really addresses your own particular needs, budget, and India’s distinctive environmental landscape.

It is such a decision that responsibly engrosses deep know-how and know-why. As a seasoned cooling tower manufacturer and cooling tower supplier in India, Tower Tech has a comprehensive array of superior quality solutions designed for optimum performance. We assist you in navigating these intricacies to get your operations cool and efficient.

For more information about industrial cooling systems, check out what we have to provide, or discuss with our professionals about your particular project requirements. We are here to assist you in achieving peak thermal management for your company.