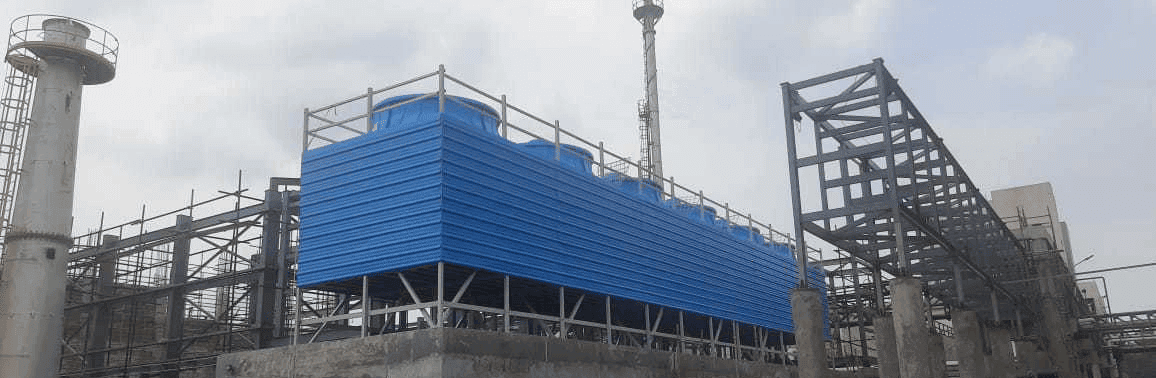

Cooling tower applications

The cooling tower system is widely used in a variety of industries, including industrial, commercial, and HVAC. The system removes heat from equipment, hot process material, and other sources in an industrial setting.

A regular heat transfer rate is required for the efficient functioning of industrial processes and machinery since they create such enormous volumes of heat. The heat must be released into the environment. A heat exchange technique is used to accomplish this. The cooling tower technique is built on this foundation.

Specifically, industrial cooling towers are common in food processing plants, petroleum refineries, natural gas plants, and petrochemical plants.

Food processing companies, petroleum refineries, natural gas plants, and petrochemical plants are all frequent cooling tower application.

Cooling towers are classified into three categories based on how water or air passes through them. Cross-flow, counter-flow, and hyperbolic are examples of these kinds. Containing draught and passive draught cooling towers are two types of cooling towers that are classified simply by airflow.

What is a Cooling Tower and How Does It Work?

Water is used to remove excess heat from the network and release it into the surroundings, usually by evaporation in cooling tower systems. Cooling towers, recirculating pumps, and heat exchangers are the three main components of a cooling system. Water is heated before passing through a heating system.

Hot water fills the tower from production machines, a commercial air conditioning system, or any other heat source, and distributes evenly at the top.

The apparatus fill spreads the water out over a broad area as it runs down the tower, increasing the water-air contact and therefore increasing heat transmission via evaporation.

The cold water then returns to cool the original heat source, and the cycle begins all over again. A part of the water system is drained to the sink through a drain valve for system balance. The line refills the cooling tower by feeding it with new water.

By utilizing a cooling tower, you may minimize the amount of heat absorbed in the water so that it allows you to reuse the same water. It helps you to conserve water, which is becoming increasingly limited these days.

There are smaller cooling towers and huge cooling towers to choose from, and you should pick the one that best fits your requirement.

Applications of cooling tower

Small cooling towers are suited for household usage since they only manage a few liters of water, but giant cooling towers can handle many more liters of water and are suitable for industrial use. The cooling tower is a heat transfer system that helps to remove waste heat from the water-based process system fluid.

The cooling tower’s primary function is to prevent the heat absorbed by the flowing cooling water system. The following are some of the applications of the cooling tower:

- Air compressors with a water cooling system

- Blow Molding and Compression Molding Machine

- Machinery for die casting

- Plant for deep freeze and anodizing

- Plant for generating electricity

- VAM machinery and liquid air conditioning systems

- Machines that process natural gas

- Stations that generate electricity

- Oil and gas facilities

- Plants that are semi-conductor

- Hydrocarbon facilities

- Boiler Application

- Chiller Application

- Die Casting Application

- Furnace Application

- Fot Dip Galvanizing

- Hydraulic Press

GET IN TOUCH WITH US !

Final Words

Cooling towers are becoming eminent for every industry. If you are looking for high-quality cooling towers that could be set up in your place, then you should consider contacting Towertech for the best services.