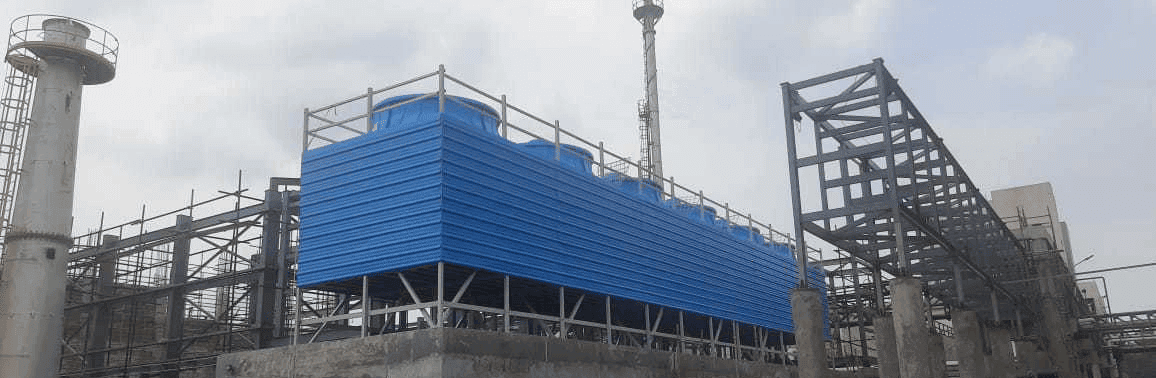

Pultruded FRP Cooling Tower

Towertech has the best-dedicated team, which creates the Cooling Tower with induced draught design to make them more efficient than others. They are the most recent advancements in cooling tone electricity usage.

With the use of technology, strong steel sheets, aluminum sheets, bronze, alloy, and nickel, all are employed in making the cooling towers that have FRP materials to make them corrosive resistant. The fiberglass towers we offer enable cost-effective external heat dissipation in air conditioning refrigeration.

The FRP cooling tower (fiber-reinforced polymer) is a polymeric component that is extensively applied in industries. It could also withstand harsh environments and protect against rusting, germs, and bacteria present in freshwater.

These FRP counter-current towers are used to reduce the temperature of hot water and maintain it at a specified level. Our FRP cooling towers are built with advanced cutting-edge technology which helps to achieve maximum efficiency.

As a result, it is capable of withstanding stress and strain. These structures are designed specifically for usage in heavy industrial segments.

The energy efficiency of the FRP Tower

With growing energy consumption and a focus on environmental stewardship, it’s critical that cooling towers are engineered, manufactured, implemented, and operated in an energy-efficient manner.

Amongst these methods, you may employ to improve efficiency through the following:

- Air-cooled systems use more energy than water-cooled and open-circuit systems.

- A more detailed design approach for the cooling tower might greatly reduce the cost savings.

- To ensure the continuous performance of the cooling tower, regular functional cleaning is required. The maintenance period depends on the type, size, and environmental factors of the tower, such as the location of the tower.

Fascinating facts about FRP Tower

- The pultrusion technique is typically preferred because of the materials used in its production and how beneficial it is for smaller cooling towers.

- Carbon fibers are inexpensive and need little management. On the other hand, concrete slabs are still utilized in large frameworks.

- The tower shell is composed of durable fiberglass reinforced plastic (FRP) with enough tensile rigidity to withstand strong winds and shocks. For a better quality of life, UV-stabilized polymer is combined with a gel coat.

- It is resilient to environmental effects, and even if little damage occurs, it is simple to fix.

- These Industrial Strength Cooling Towers may be constructed up to 18 x 18 meters in size, with a maximum flow rate of 5000 m3/hr. per unit.

FRP Cooling Tower Merits:

FRP cooling tower structures are one of the finest materials for cooling tower construction since they do not corrode, rust, or wrap in severe conditions. The benefits of using an FRP cooling tower are listed below.

- Easy to clean and maintain

- High resistance to corrosion

- Not affected by acid rain or snow

- Lightweight design

- Ideal for dry and wet operation

- The maintenance cost of the tower is very low.

If you are looking for an FRP cooling tower manufacturer in India, then you should go for Towertech. At towertech, we provide the best types of cooling towers according to your needs.