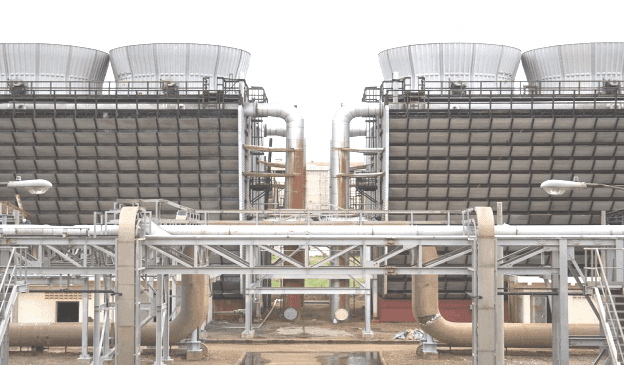

Cooling towers are found in many industrial applications, and they seldom receive the recognition they should. Cooling towers keep our systems cooled and online day and night, 24 hrs a day / 365 days a year without so much as a murmur of complaint. On the opposite side, cooling towers typically also have the single largest water use of any of the operations in any plant, and usually the majority is lost to evaporation (which is necessary for cooling to take place, and it’s a cost to run).

The first step to weather saving and water cost savings is to be able to get a handle on what your evaporation loss, or evaporation volume, is. By optimising operating practices and efficiencies for cooling and evaporation applications, we can turn a significant water loss into a managed availability.

What is Cooling Tower Evaporation Loss?

Evaporation is the most important heat rejection method in a cooling tower, and the very basis of its operation. As warm water from your industrial process flows through the tower, a portion of that water will evaporate into the flowing pathway of air. The significant amount of thermal energy removed from the remaining water in the process of changing from liquid to vapour utilises a vast amount of energy for cooling the water before it is processed back into your system.

Now, while evaporation is ideal, the act of evaporation cannot be uncontrolled or excessive, as it will cause wasted water, increased costs of chemical treatments, and higher operating costs. Effective cooling tower water saving does not involve eliminating evaporation, but rather the ability to evaporate as much water as possible, water into the air, as efficiently as possible.

Key Factors That Influence Evaporation Rates

The volume of water that is lost to evaporation is not a defined number and is relative to a large number of operational and environmental conditions. Understanding these conditions will put you in a better position to manage the performance of your tower.

- Heat Load – The single biggest influence, the heat that your tower needs to reject from your process translates to the volume of water that has to evaporate to provide the required cooling. As the heat rejection increases, so does the water lost to evaporation.

- Ambient Conditions – The temperature and relative humidity of the surrounding air influence evaporation directly. Evaporation occurs much faster on a hot, dry day when compared to a cool, humid day.

- Airflow Rate – The volume of air that’s moved through the tower by the fans has a direct correlation to the rate of evaporation. The more air you have, the more evaporation you will generally have.

- Water Quality – Poor water chemistry can lead to scale on the fills and create a mineral layer that acts as an insulator and reduces the PD efficiency of the heat transfer.

Smart Tips for Water Conservation in Cooling Towers

Controlling cooling tower evaporation loss can be accomplished through a proactive operational and maintenance plan. Below are a few of the most efficient water conservation actions you can take.

- Increase Cycles of Concentration (CoC): If done properly, you can increase your CoC by optimising your water chemistry and managing your “blowdown” or “bleed-off” rate. By changing how you operate, you could be using your water longer to the point that you do not have to waste it.

- Invest in High-Efficiency Drift Eliminators: A common mistake people make is confusing evaporation losses with drift losses. Drift is liquid water from the tower that finds its way into the atmosphere.

- Control Air Flow with Variable Speed Drives (VSDs): By outfitting demanding fans with VSDs, you can adjust air flow to meet the real-time cooling process demands and curtail energy consumption as well as unnecessary evaporation during non-peak cooling periods.

- Establish a Routine Maintenance Program: A clean tower is an efficient tower. Establishing a routine clean-out of the tower basin, nozzles cleaning/checks, and professional cleaning or replacing the fills will save you water in the long run by avoiding significant buildup of scale and biofilm, all of which impede thermal performance and water losses.

Conclusion

Evaporation loss is controlled by operation and is not a fixed cost. The only way to reduce your water footprint and decrease your operational costs of cooling tower use is to have a plan in place for incorporating water conservation strategies with operational choices and upgraded quality components.

As a leader in Tower Tech cooling towers and a suite of high-efficiency parts, we care greatly about helping our customers achieve the best operations they can. When you update to newer components, you aren’t just updating a part, you are investing in a sustainable, profit-focused future.

Upgrade your cooling tower’s performance. Contact Tower Tech for a quote on high-efficiency parts.