Still Pouring Pounds of Poison? Why It’s Time to Ditch the Chemicals in Your Cooling Tower

It’s like this all the time, isn’t it? The operation of a commercial cooling tower by a business involves the continuous challenge of the same three enemies: scale, corrosion, and microbes. The answer for a long time has been a never-ending chemical dosing cycle using, storing, mixing, and throwing chemicals that are harmful to the environment just to keep the system working. But really, how effective, or how safe, does it still look? It is a costly, inconvenient operation that puts the person handling the drum at great risk every time, and it is very likely that it will cause eventual equipment damage and the compliance problems that will be difficult to solve later on.

You have probably heard the saying: “Work smarter, not harder.” What if we were to tell you that this is exactly how you should manage your most valuable HVAC asset? Facility managers and building owners across India are now making the smart choice by implementing non chemical water treatment cooling towers. This shift fundamentally changes how you view system management, proving that going chemical-free isn’t just about being “green,” but about making smart financial and operational decisions that simplify your life and compound profits over time.

The Powerful Role of Going Chemical-Free for Your Bottom Line

Did you know that just 1mm of scale buildup can reduce your chiller’s efficiency by over 10%? That is pure money evaporating into the atmosphere. The biggest reason for moving away from traditional methods isn’t just about being “green”; it’s about making smart financial decisions that compound over time. Let’s see what all you can achieve by making the switch to a chemical-free cooling tower treatment:

Eliminating the Hidden Drain on Your Energy Bill

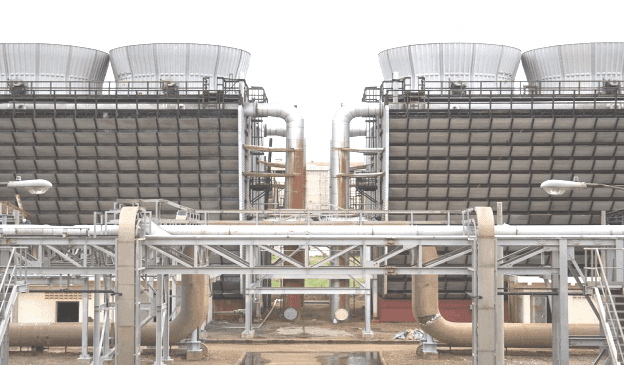

Scale is the insulator your system never asked for. When water that is in contact with your heat exchanger is dirty, there is a need for a longer chiller run, and as a result, significantly more power will be consumed to achieve the same cooling. Installing a non-chemical water conditioning system means that you are preventing the formation of scale in an active way, and thus, the heat exchange surfaces are continuously kept clean. This cleanliness is the main factor behind better cooling tower efficiency. The cleaner your system is, the less electric power it will require, it’s really that simple. If you wish to put in energy-efficient and sturdy systems, have a look at our latest cooling tower range.

Achieving Genuine Cost Savings, Instantly

Think beyond the sticker price of biocides. Traditional treatment methods require high “blowdown”—the process of dumping water to reduce the concentration of dissolved solids. This wastes thousands of litres of water every week. Non-chemical solutions allow you to run the system at much higher Cycles of Concentration (CoC) safely. This reduction in water consumption, combined with the complete removal of chemical purchasing and storage costs, adds up to truly cost-effective cooling tower maintenance. No more surprise chemical deliveries, no more high disposal fees.

Protecting Your Capital Asset

One of the main reasons is that chemicals, in particular corrosive ones, which are used to remove the existing scale, damage metals. They gradually, however, are the biggest contributors to the outer layers forming on pipes, chillers, and racks of the towers. In fact, this kind of wear and tear may also result in holes in the metal parts that are inaccessible to cleaning. Advanced water treatment devices use different methods; they do not release chemicals into the water but stabilize it and condition minerals to be non-sticky. This soft yet efficient technique has a great effect on the life of your cooling tower as well as the HVAC equipment that is attached to the system, thus most likely the period of time during which you have to replace these parts will be extended.

The Comprehensive Checklist for Safer, Smarter Operations

A policy review helps you get your insurance affairs in order; similarly, a check-up on your water treatment strategy can help you get your facility operations in order. A thorough move to a non-chemical approach allows for the examination, verification, and accurate documentation of improved operational standards across the board.

Check out the operational improvements that should be your new “bible” for maintenance:

Safety and Compliance Verification:

This is about verifying and ensuring that your staff is not exposed to corrosive or toxic chemicals daily. The accuracy of your health and safety protocols guarantees that your workplace is genuinely safer. Switching to reduced chemical dependency in HVAC systems simplifies training and compliance with environmental discharge regulations instantly.

Water Quality Analysis:

The next step is verifying continuous water quality. Systems often include cutting-edge cooling tower water filtration that removes suspended solids, silt, and debris that chemicals simply cannot touch. Better filtration leads to fewer deposits and a far cleaner system overall.

Sustainability and Documentation:

At this stage, you must ensure that your discharge is compliant, clean, and reusable. We help you verify the inclusion of sustainable water treatment solutions in your operational reports. Confirming this step means you are not just compliant, but you can confidently report on your eco-friendly cooling tower treatment credentials to stakeholders.

The Stability Factor: Consistent Performance, Zero Guesswork

One of the biggest problems with chemical treatment is an issue of inconsistency. The dosage has to be changed all the time depending on the weather, load, and water quality – it is a perpetual struggle to bring the levels to perfection.

On the other hand, non-chemical methods keep the water conditioned continuously and evenly by either a physical or an electrochemical process. This reliable delivery ensures your equipment is protected 24/7, leading to a huge reduction in unexpected scaling issues or biological fouling. You reduce the chances of sudden shutdowns and unnecessary maintenance calls—a key benefit delivered by reliable cooling tower services.

The Final Word: Invest in Simplicity

The change from chemical to non-chemical water treatment in cooling towers is certainly not a temporary trend, but it is rather a considerate move to the future of your plant. The decision to use this method means that you are choosing to save money instead of spending it again and again, giving priority to the safety of the employees instead of the risky handling, and ensuring that the equipment will last longer instead of it breaking down quickly.

You make the upkeep easier, stabilize the functionality, and get the assurance that your operation is running at its best without the chemical burden. Do not let chemical dependence be the reason for your efficiency and safety to be lost any longer. The time has come to make the right, safe, and eco-friendly choice of cooling.