Cooling towers are said to be one of the most significant components of any of the industrial processes. It has several different types of structures like tall, square, cylindrical, or open-topped that help the industries to bring down the temperature of the water. As the technology has advanced in ample ways, it has also shown a positive impact on the cooling towers’ performance.

The extraction of waste heat from the system using water has been made easy. Moreover, the cooling tower can now perform its work in many different ways at a time. In this article, we have discussed the working as well as various parts of the FRP cooling tower.

How is the working of the FRP cooling tower?

Firstly, the hot water enters and pumps up to the header from the inlet of the FRP square cooling tower. The title contains sprinklers and nozzles that help to increase the surface area of water by spraying it. After that, the water enters into PVC filling to slow down its speed.

In addition, fans are used at the top of the cooling tower to elevate air from the bottom to the top. Now, the formation and a good connection between the hot water and air occur because of slow speed and more water contact area. The water temperature is reduced by evaporation, and the cool water accumulates at the bottom of the tower.

Now, moving further, let’s dig into more information about different types of cooling towers.

Types of FRP cooling towers

There are different types of FRP cooling towers. Let us understand more about them by reading further.

- Mechanical Draft Cooling Towers

The primary function of the mechanical draft cooling tower is that it consists of fans and other mechanics that allow the air to circulate throughout the tower. Centrifugal fans and propeller fans are used in this mechanical draft tower.

Additionally, the ice on the cake part of this tower is that it can be used inside the buildings because they tend to be more effective than the natural ones. It is more effective with more power consumption. This tower contains two sub-groups. They are:

- Counterflow cooling towers

To cool the air, the counterflow cooling tower lets the air move upward, with the water flowing downwards. They are capable of saving more energy and are often more compact in footprint than the counterpart towers.

- Crossflow cooling towers

Now, talking about the crossflow cooling towers, they have the flow of the hot water downwards from the distribution basin, whereas through the cooling tower structures, the airflows in the horizontal path. Crossflow cooling towers are more prone to freezing and are less efficient. They are also called tall towers. It is the most straightforward task to maintain this tower but is a piece of relatively more expensive equipment.

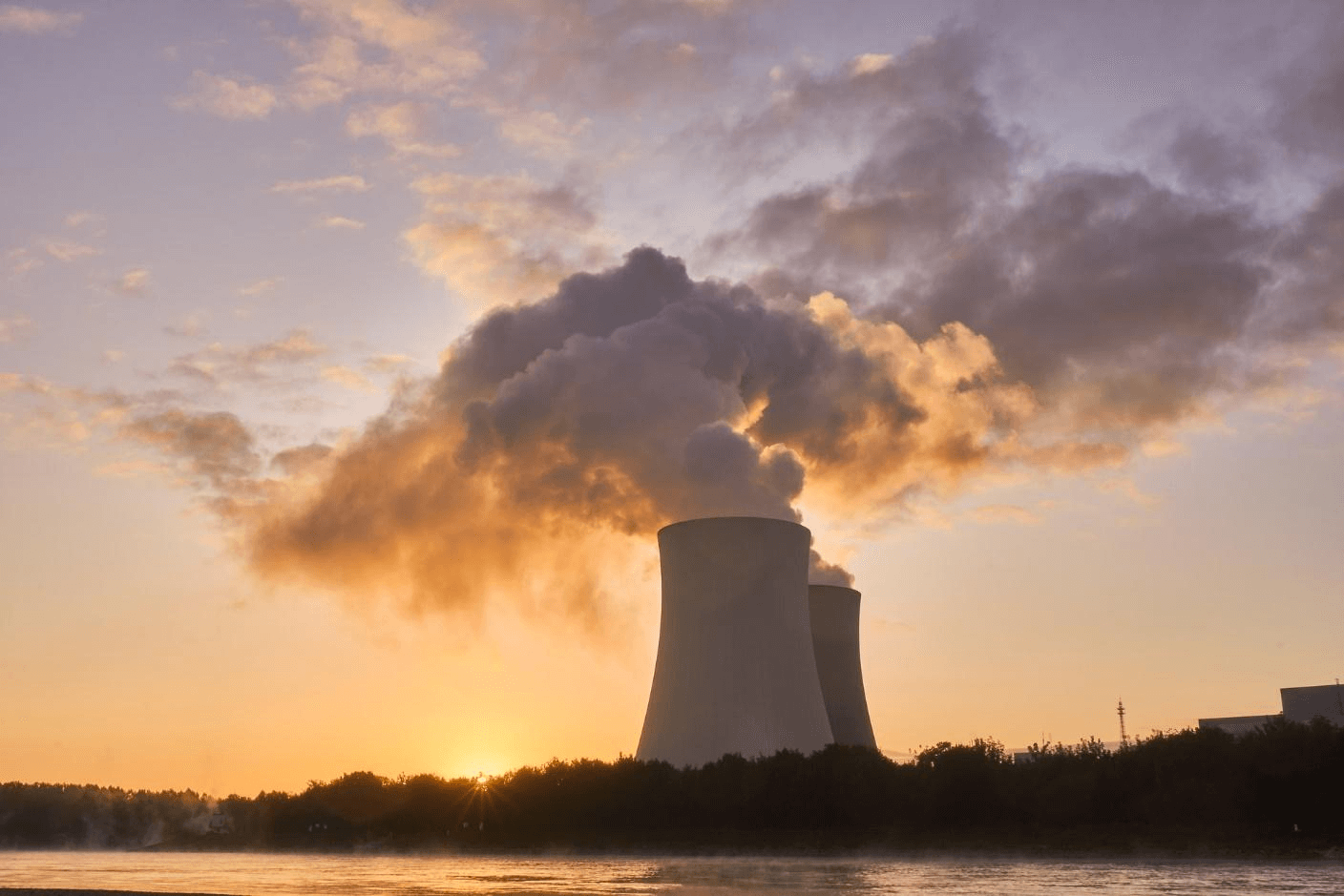

2. Natural Draft Cooling Towers

As these cooling towers depend upon natural convection, they are known as natural draft cooling towers. They are sometimes made of steel or concrete. One can find these natural draft cooling towers in the places like power stations and energy-intensive facilities such as oil refineries, natural gas plants, and petrochemical plants.

However, the leading cause of using this tower is to remove heat from the circulating water system. Due to the different densities of internal air, the movement of air inside the tower is further responsible for circulating it throughout the tower.

What are the different parts of the FRP cooling tower?

There are various cooling tower parts responsible for its effective working. Some of the key parts are:

- Eliminator

The eliminator is located at the top of the tower allowing only hot air to pass. The water cannot pass through it.

- Float valve

This valve is used in cooling applications that rely on air-to-water contact and constant water flow for evaporative cooling. Its main aim is to maintain the level of the water.

- Spray Nozzles and Headers

Through spray nozzles and headers, the water surface area is increased by components and is also responsible for increasing the evaporation rate.

- Body

The construction of the frp cooling tower is of fiber-reinforced plastic. It is designed in such a way that the outer surface often protects the inner parts of the cooling tower.

- PVC Falling

PVC Falling helps the hot water to slow down its falling speed.

- Mesh

The primary function of the mesh is to stop the particles from entering the cooling tower. When the fan at the top of the building is switched on, it uses atmospheric air for the stoppage. By preventing the particles, the mesh makes the system run smoothly.

- Bleed valve

The concentration of salt and mineral present in the water is controlled with the help of a bleed valve.

Hence, we hope this quick guide helps you to know about frp cooling tower if you aim for a long-time investment in it.