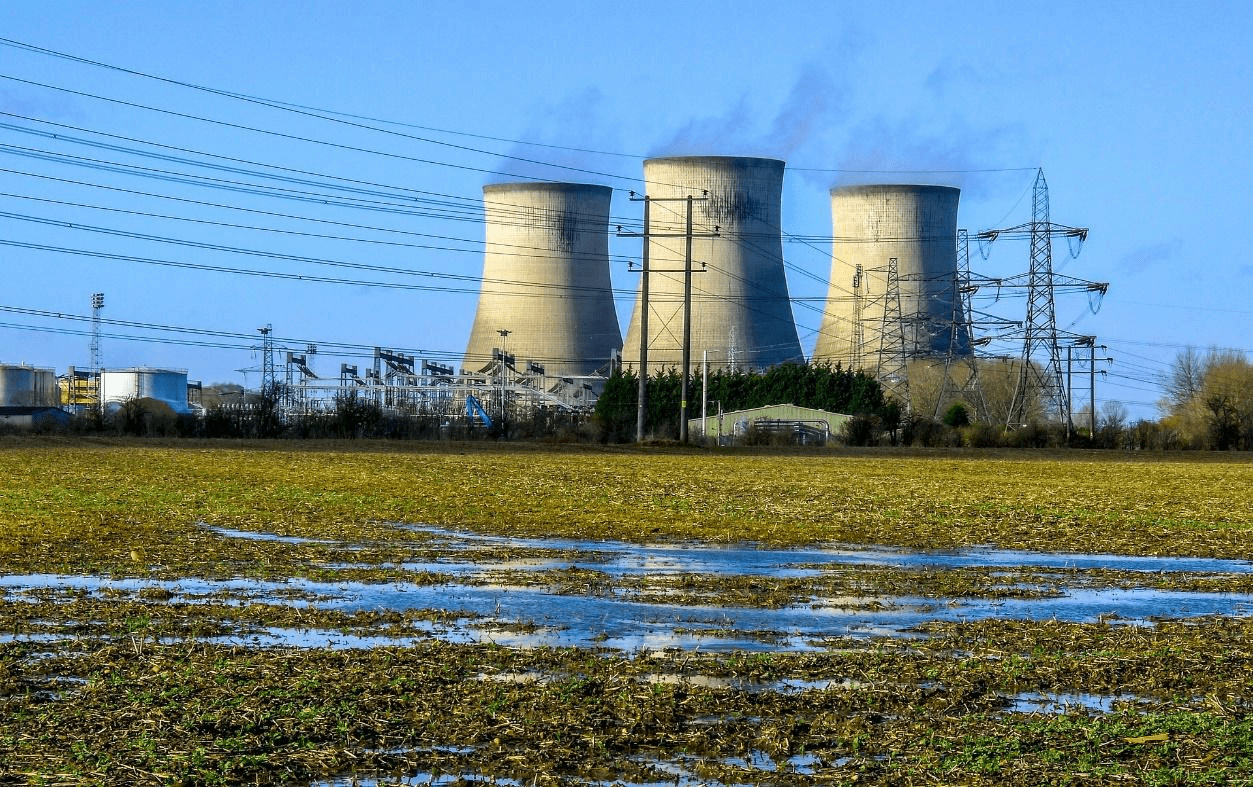

Evaporative towers, often known as cooling towers, are used to dissipate heat from a liquid through a gas. The gas phase is often made up of air or water vapor, and the liquid phase is made up of water. In other words, a heat exchanger between air and water that, by removing heat from the liquid, causes just a small amount of water to evaporate relatively to the total amount of water in circulation.

Excess heat is frequently generated during industrial operations, in HVAC systems, and during the production of electricity. Evaporative towers are one of the most effective and cost-effective options on the market among the many options available to accomplish this purpose.

How Do Evaporatie Cooling Towers Work?

The most often utilized model is the forced open circuit cooling tower’s operating concept. A counter-current flow of cold air cools the process fluid (water) in evaporative towers. In order to contact the flow of cold air drawn in by the grids, the water is sprayed from nozzles positioned above the heat exchange pack.

A portion of the water evaporates during the transit in the heat exchange pack, and the drop eliminators above the distributor help to separate the larger drops from the airflow. From the tower’s summit, hot, saturated air is expelled into the environment.

In the basin, the cooled water gathers before being sucked up by a filter-equipped outlet. As soon as the water to be cooled comes into touch with the atmosphere, the circuit is of the open kind.

The Advantages Of An Evaporative Cooling Tower

Because of the evaporative cooling towers’ straightforward structural design and high cost-to-kW efficiency, these systems are frequently employed in both the civil and industrial sectors.

If a final fluid temperature below ambient is sought, evaporative cooling towers are more efficient than dry air cooling. Assoclima agrees that the subtracted heat for 1 kg of water is 2,200 kJ per °C while the removed heat for 1 kg of air is roughly 1 kJ per °C.

Evaporative cooling, among other things, makes it feasible to drop the outlet water temperature to a point close to that of a wet bulb—a temperature that is lower than that of a dry bulb. The lowest temperature that evaporation of water can reach in the air at constant pressure is, in fact, the wet bulb temperature.

An evaporative cooling tower uses up to four times less energy than other cooling systems in terms of energy consumption. It is obvious that using an evaporative tower is one of the best options when we take into account both the rising concern over global warming and energy consumption.

What Is The Function Of An Evaporative Cooling Tower?

A water cooling tower is a large heat exchanger that is used to cool water by transferring heat from the surrounding environment to the atmosphere and returning cooler water to the chiller. Warm water from a chiller is sent to a water cooling tower. Because it gains heat in the chiller’s condenser, this warm water is referred to as condenser water.

Usually, the chiller is down below, perhaps in a basement. The cooling tower’s function is to lower the water’s temperature so that it can return to the chiller and absorb more heat.

Why Is An Industrial Evaporative Cooling Tower Needed?

An industrial evaporative cooling tower is a vital part of many refrigeration systems. It is used in many manufacturing facilities, such as steel mills, power plants, and chemical processing facilities where process cooling is required. Large business structures like airports, schools, hospitals, or hotels can also benefit from the comfort of cooling provided by a commercial cooling tower.

The heat collected in the circulating cooling water systems used in oil refineries, power plants, food processing plants, natural gas processing plants, petrochemical plants, and other industrial facilities is removed using an industrial cooling tower, which can be bigger than an HVAC system.

The rate of the world’s needs and requirements for manufactured goods has significantly expanded along with the rate of global population growth. This has compelled the industrial sector to produce an increasing number of goods each day, which increases the heat produced during the manufacturing process. In order for heat-generating machinery and processes in industrial settings to continue operating effectively, cooling must be provided continuously. The installation of an evaporative cooling tower is the most practical, cost-effective, and efficient way to remove this heat.

Conclusion

That sums up almost all the basic info about evaporative cooling towers and their functions. Anyone in the manufacturing industry understands the importance of moving towards more eco-friendly options for all the ongoing processes.

Evaporative cooling towers are beneficial for both the manufacturers and the environment. Contact Tower Tech India to know more.