No one likes to spend too much time in a facility with poor air conditioning. Buildings with good cooling, on the other hand, entice you to return, even if it’s merely to breathe in the fresh air. This is mostly due to the ongoing modernization and innovation of commercial cooling tower systems.

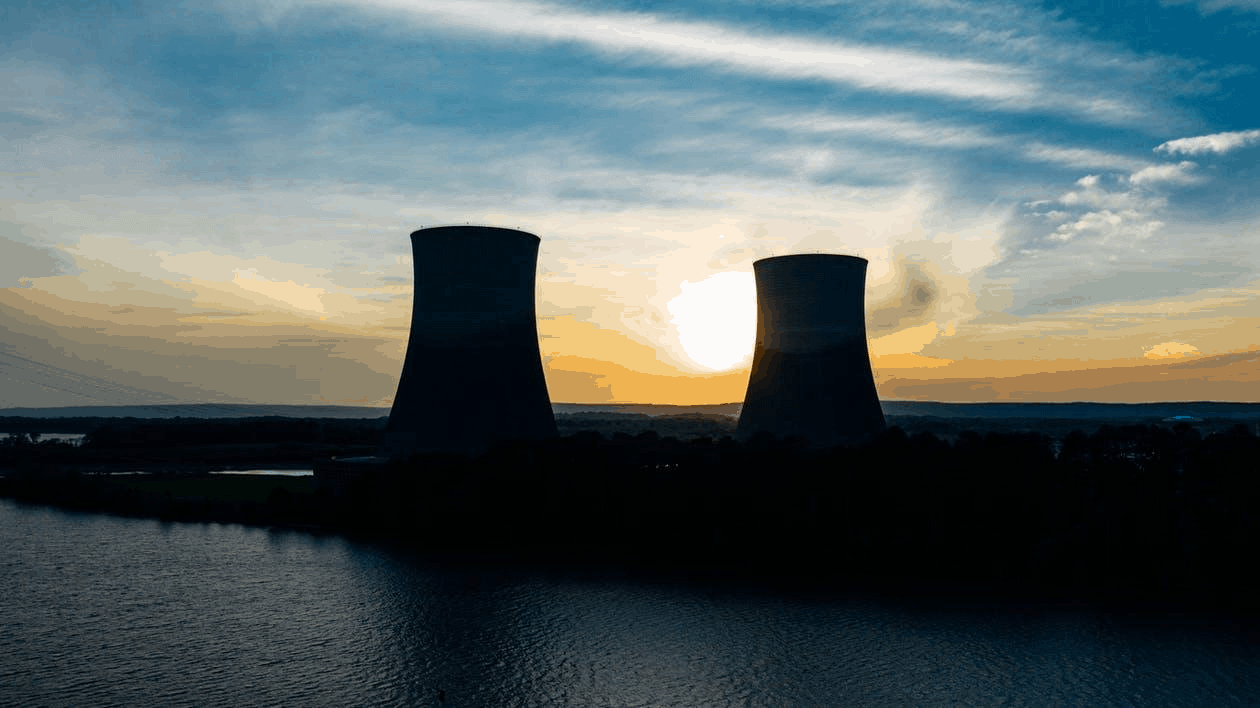

A cooling tower is a specialised heat exchanger that brings air and water into direct contact in order to lower the temperature of the water. A little amount of water evaporates, as a result, lowering the temperature of the water cycle through the tower. If you gaze down from a high-rise structure, you may spot square units with fans on top of the buildings below. Those are cooling towers for water. Let’s have a look at the working principle of a cooling tower and the various options available to choose from.

Working Principle Of A Cooling Tower

Facility owners and operators can manage and maintain their cooling tower systems more efficiently if they understand how they work.

Cooling tower systems function by extracting waste heat from a system using water and ejecting it into the atmosphere largely via evaporation. The cooling tower, recirculating pump, and heat exchanger are the three main components of a cooling system. Water is heated as it goes through a heat exchanger. The water is then dispersed throughout the top of the cooling tower, where air passes over the heated water, causing some of it to evaporate. Heat is transmitted from the water stream to the air stream, bringing the temperature and relative humidity of the air to 100%. This heated air is subsequently released into the atmosphere, creating a cold water stream. The basin’s cooled water is then sent back via a heat exchanger, and the cycle is repeated.

Types Of Cooling Towers

Now that you have understood how a cooling tower works, let’s have a look at the types of cooling towers:

1. Crossflow Cooling Towers

Air moves horizontally across the path of flowing water in a cross-flow cooling tower. It only has two air inlets. The process water is pushed to the top of the tower and discharged via nozzles into a hot water basin. The nozzles are gravity fed, with the driving force being the height of the water above the nozzles. Only the height from the pump to the top of the tower and the friction loss in the pipe, including any flow control valves, must be considered when sizing a condenser water pump for a crossflow tower.

2. Counterflow Cooling Towers

In a counterflow tower, air flows in the opposite direction (counter) to the falling water. The industrial cooling towers manufacturers design them in a manner that takes up less area than a crossflow cooling tower. The use of counterflow towers may be preferable in small areas under 750 tonnes of load capacity or in locations where reduced operating weight is needed.

3. Natural Draft Cooling Tower

Natural drafting cooling tower systems generate airflow by the utilisation of the chimney effect of the cooling tower’s real construction. Warm and wet air is less dense than cold and dry air, which allows it to ascend out of the cooling tower and into the atmosphere, drawing in denser fresh air from the surrounding environment. The difference in temperature between the warm air within the tower and the colder air outside generates the ideal airflow inside the tower. When it comes to cooling towers, natural draught cooling towers are the best option for cold and humid locations as well as for high winter loads.

4. Induced Draft Cooling Towers

In induced draft cooling towers, incoming cooling water is injected throughout the cooling tower by a spray distribution header. Air enters the cooling tower’s interior through appropriately built ‘louvres.’ Big fans pull air through the baffled region, cooling the water.

5. Dry Cooling Towers

Dry cooling towers are among the cooling towers intended to achieve the same goal as other towers: to remove as much surplus heat as possible. Extra heat from machinery and industrial operations may be hazardous to system performance and can pose a threat to our personal safety.

Summing Up

Now that you’ve finished reading this article, you will be able to speak confidently about cooling towers, including how they work, types of cooling towers and where they are utilised. In order to not only secure your safety but also to preserve your system’s efficiency as high as possible and to save money and effort in the long run, it is essential that you choose the most suitable cooling tower.

Contact us today to substantially cut your cooling system’s running expenses, boost cooling efficiency, and eliminate cooling tower management difficulties!