You might have already heard about industrial water cooling towers. But do you know what really is it? Today, we are going to share with you what really a cooling tower is, how it works, and what are its benefits.

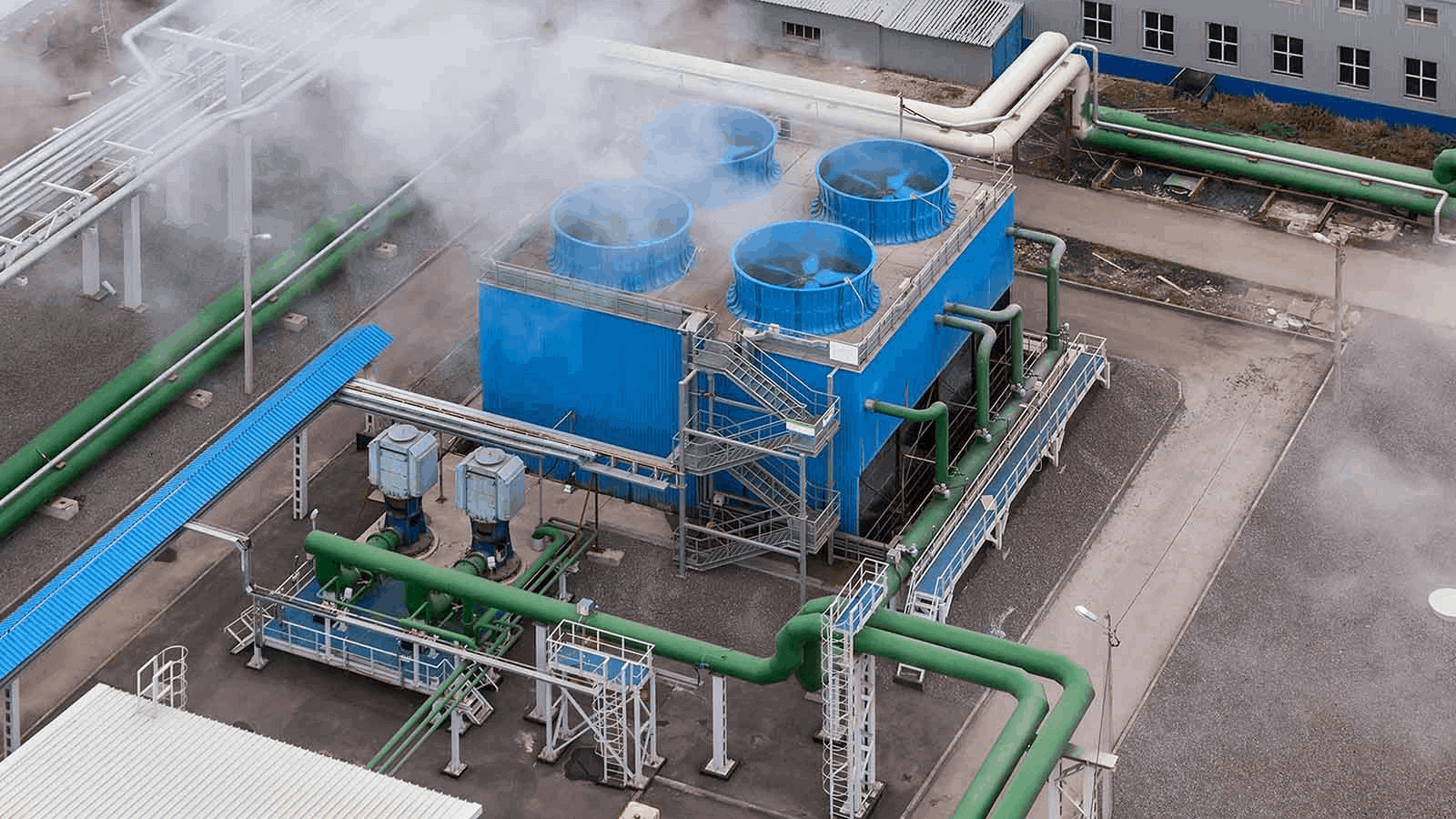

Have you passed by an industrial plant or a factory and saw an odd-like structure that emits a white smoke? Well, that’s what you call a cooling tower. A cooling tower is a piece of industrial equipment that is also known as a heat exchanger.

What is a cooling tower?

An industrial water cooling tower, or simply cooling tower, is a device or structure that is intended to expel the excess heat absorbed in the circulating cooling water system of a building, specifically in industrial facilities such as food processing plants, petroleum refineries, natural gas processing plants, power plants, petrochemical plants, and semiconductor plants, to name a few. This process helps lower the water temperature. The circulating cooling water system could be used for HVAC (Heat, Ventilation, Air Conditioning) systems, manufacturing processes, and generation of electricity.

Industrial plants use heavy-duty machinery for their processing. These machines produce heat that may affect a lot of areas inside the industrial plant. Industrial processes will make the air humid, causing the water to warm up. As a result of this, the heat that accumulates around the area could become a root cause of more complex problems. Two of which are corrosion and fouling.

Fouling and corrosion damages in cooling water systems can be a real headache. When machines become corrosive, they most likely begin to malfunction sooner than later.

- Corrosion damage in cooling tower parts is caused by the reaction of the metal surface with its environment.

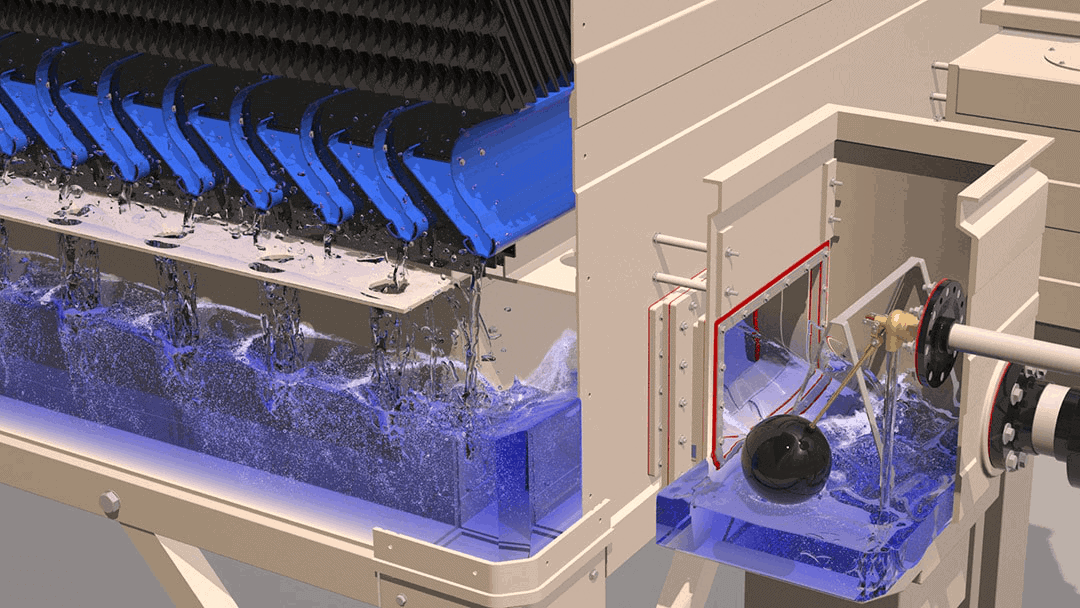

- Fouling, on the other end, is a totally unpleasant phenomenon that affects heat exchangers and heat transfer. The fluid that flows into the cooling tower is not totally clean. It may contain organic deposits, oil, grease, chemicals, or dirt. These elements may accumulate on the surface of the heat transfer, forming an unwanted coating. This phenomenon will significantly reduce the heat transfer coefficient which in return can cause heat exchanger thermal efficiency reduction.

How does a cooling tower work?

The different types of cooling towers offered by various water cooling towers manufacturers operate in different ways. The one that is mostly used by industrial businesses is specifically referred to as an evaporative water condenser. This equipment operates in such a way that the existing water supply (that is supplied to the heavy machinery and that circulates around the plant) is pumped into a chamber that removes the excess heat from the liquid and then converts it into water vapor. The water vapor is then expelled into the atmosphere.

Breaking the heated water and releasing the heat in the form of vapor makes the remaining water cooler. The cooled water is then pumped back into the system. This time, the water can be used once again in various applications including as potable water, process water, or merely just general service water.

The primary benefits of a cooling tower

When industrial plants obtain water from a natural source, another kind of machine is needed to filter the water supply. This machine will require additional power which can significantly increase electric consumption and costs. Aside from filtering the water, it also needs to be cooled down before it can be used for industrial processes. An air condenser is usually used for this purpose. Again, this machine also consumes a lot of energy. With the use of a water cooling tower, the need for an air condenser or filter machine is eliminated. This will not only help avoid consuming additional energy, acquisition of water from a local river, lake, or other natural sources will also be greatly reduced.

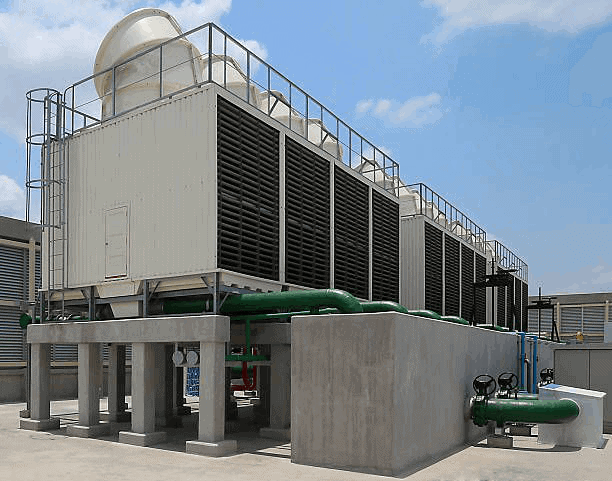

This device seems like a huge investment, but on the contrary, cooling towers are generally inexpensive. Cooling towers are relatively easy to handle or manage. They are also easy to install and maintain. You only need to clean the motors at least once in every couple of years and to perform a routine inspection once a year to ensure everything is well and to identify potential damages.

Water must be maintained at a steady temperature. Otherwise, it can attract contaminants that can cause machines to malfunction or cause defects in the products being processed. Luckily, that is what these devices are designed to do. It can purify the industrially used water and make it usable again. This does not only minimize the acquisition of water from natural resources, this likewise helps greatly reduce waste.

The industrial water cooling towers have proven to be very energy-efficient, too. These have special features that enable you to reuse wastewater. They also have a pretty low electricity consumption and a long lifespan so there is a guarantee that the device will serve you good for a long period of time.

Cooling towers offer a convenient way of managing the heat circulation inside a processing plant. These cooling towers, especially the evaporative ones, are very much effective in ridding your plumbing system of hot water. Even in low humidity, these towers can still function well. Having cooled water circulating throughout the system can reduce the risk of machine overheating. This is beneficial to power plants, gas processing, and food processing plants. You also don’t have to worry about the noise because these devices operate at a low volume.

To sum it all up, the major benefits one can derive from water cooling towers boil down to energy conservation, water preservation, and pollution reduction. Cooling towers have become a trend in the innovation of industrial plants nowadays. The benefits of using this water cooling equipment far outweigh the reasons why you shouldn’t invest in one in the first place. The industrial applications of the cooling towers have been proven advantageous by several companies.