Large industries use machinery and appliances that generate a lot of heat such as refrigerators, engines, turbines and the likes. In order to reduce heat and to cool down the air, industrial plants utilize a nearby river, lake or any body of water as a source of water. This becomes another cause of many kinds of pollution. Fortunately, science has come up with an effective solution to this problem. With the invention of the cooling tower, it may not be such a problem anymore. But what really is a cooling tower? How does it work and what are its types? This article aims to provide answers to these common questions about the cooling tower.

What is a cooling tower?

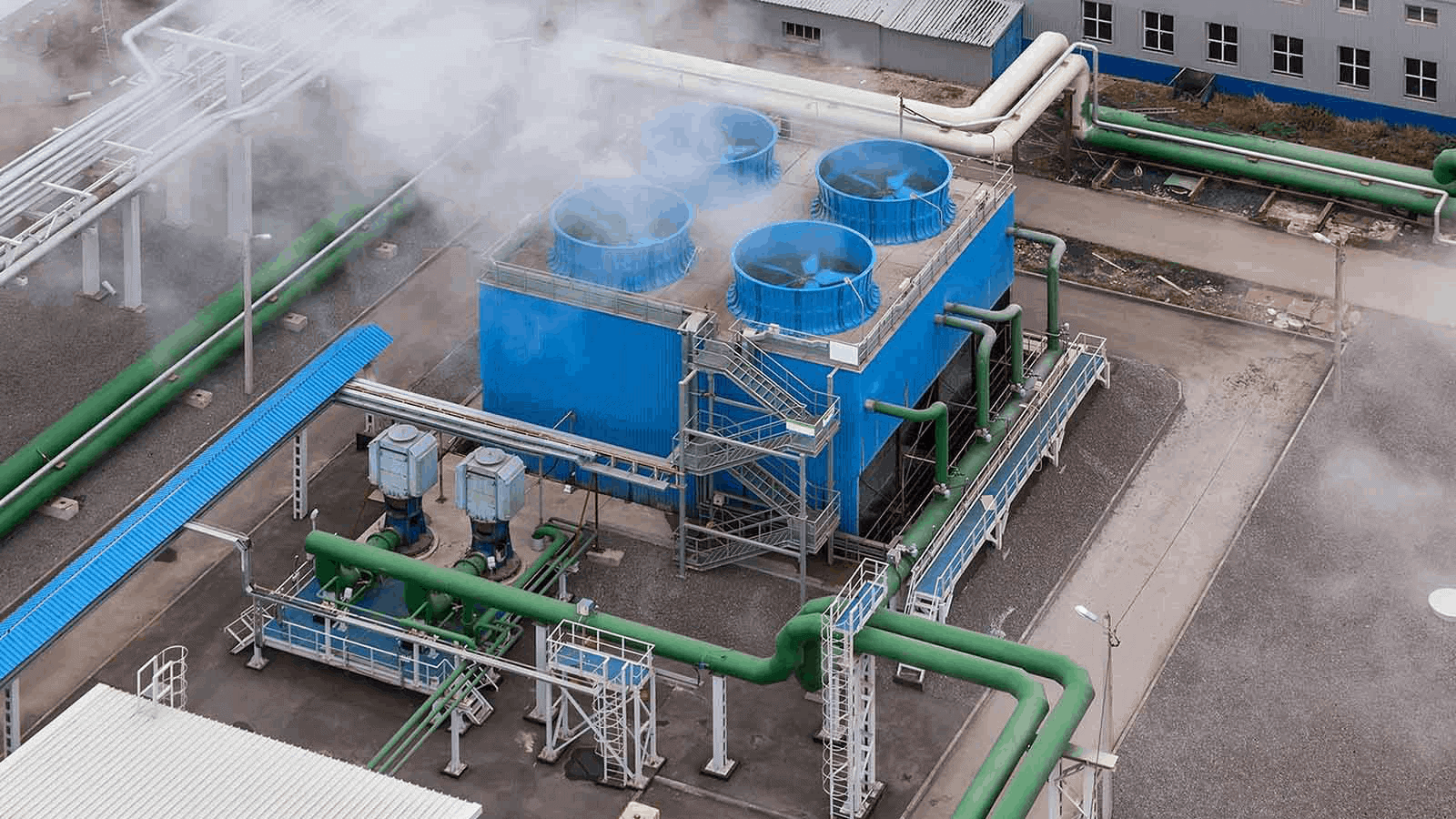

A cooling tower is a tall, open-topped, cylindrical structure that is used to transfer processed waste heat into the atmosphere. This heat rejection device uses water to eliminate unwanted heat from a building or industrial plant. Heat elimination is done by cooling the water stream and keeping the temperature lower. This structure or device is responsible for cooling the water generated from heating, ventilation, and air conditioning (HVAC) or industrial comfort cooling process.

How does a cooling tower work?

A cooling tower works on the principle of eliminating the processed heat from the water and keeping the working fluid cool through either evaporation or relying on air to cool down the water. When evaporation is used, a small portion of the fluid that is recirculated through the unit is being left to evaporate into a moving air stream, leaving the rest of the water stream cool. The process also cools down the working fluid to almost wet-bulb air temperature.

The closed-circuit dry cooling towers, on the other hand, depend solely on the air to keep the working fluid cool to almost dry-bulb air temperature. When the cooler air and the warm water are mixed, latent heat of vaporization os released, providing the water with a cooling effect.

Cooling towers use the evaporative heat rejection method. The extracted heat that is being transported to the air stream from the water stream increases the relative humidity and the temperature of the air to 100%. This air is then released into the atmosphere.

Cooling tower applications

A cooling tower is one of the most critical parts of an industrial process and is also a key component of a refrigeration system. The primary application of the cooling tower is to provide cooled water for manufacturing, air-conditioning, and electric power generation, making the operation of systems that need cooling more energy-efficient and cost-effective. You can see it being used in steel mills, power plants, chemical processing plants, and manufacturing buildings that require process cooling. It is also often used in providing comfort cooling for large structures such as hotels, schools, airports, hospitals, and other gigantic commercial buildings.

Different types of cooling towers

There are several cooling systems offered by water cooling tower manufacturers today. Each one of these systems available on the market varies in size, capacity, type of air induction into the tower, and mechanisms of action. Among the most commonly used cooling towers are the natural draft cooling tower, cross-flow cooling tower, round cooling tower, pultruded FRP cooling tower, and field-erected cooling tower.

Size

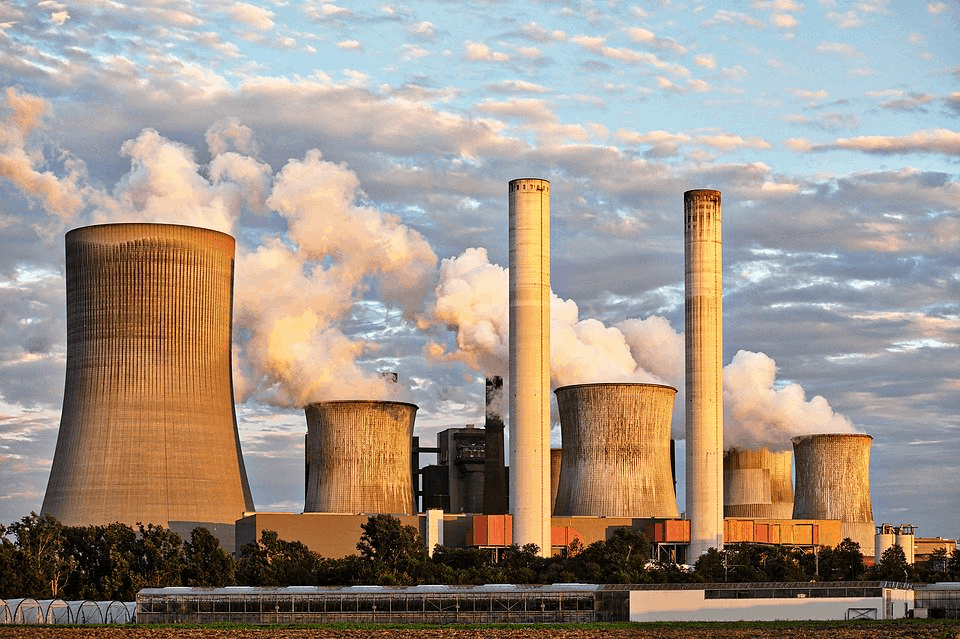

Cooling towers can be compact or gigantic. The most compact cooling towers, usually small roof-top units, are specially designed for smaller buildings like residential structures. They can cool merely a few gallons of water per minute supplied in small pipes. The most gigantic cooling towers, on the other end, can handle a large water stream and can cool thousands of gallons of water per minute supplied in pipes. Large hyperboloid cooling towers are used in large power plants and industrial buildings that need constant process cooling.

Build

Cooling towers are available in two primary builds- field erection type and package type. The field erection types are large units that are used in huge processing and manufacturing facilities like power plants, oil refineries, and steel processing plants. They are often custom made and are designed to meet particular specifications.

Whilst, the package type cooling towers are pre-fabricated or pre-assembled. They are way smaller than the field erection types and can easily be transported from one place to another. Most of the package type cooling towers have a shell that is made of durable, heat resistant and corrosion-free material like fiberglass-reinforced polyester. This type is often used in office buildings, schools, malls, hostels, and hospitals.

Heat transfer methods

Cooling towers also vary in heat transfer methods used. The different cooling towers with different heat transfer methods are:

- Dry cooling towers

- Hybrid cooling towers

- Open Circuit cooling towers or wet cooling towers

- Closed-circuit cooling towers or fluid cooling towers

Type of draft

In terms of the type of draft, there are three main classifications of cooling towers- the natural draft, fan-assisted natural draft, and mechanical draft. Under the mechanical draft are the induced draft towers and forced draft towers.

Airflow generation methods

Cooling towers are also classified through the airflow generation method used. There are two different kinds of cooling towers based on airflow generation methods. These are the counter-flow cooling tower and the crossflow tower.

Cooling towers are designed primarily to cool water. This huge heat exchanger is not only used in large industrial plants and manufacturing facilities, but are also in high-rise buildings and even on smaller establishments like schools, hospitals, offices, and commercial buildings. When choosing a cooling tower, you need to carefully think of the specific needs of the structure where you intend to install it in order to pick the right one. Understand that this heat rejection device is classified in different ways and each type or classification has its own unique features.