A cooling tower needs to be properly cleaned and maintained in order for it to function with maximum efficiency. But how can you be able to ensure that the cooling tower is properly maintained? Well, we have here a maintenance checklist for you.

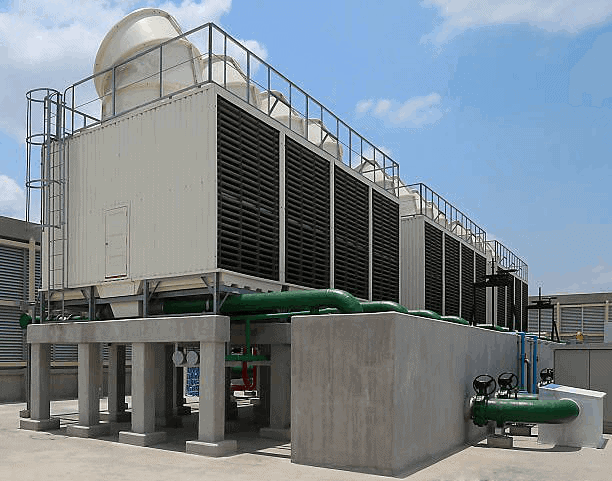

The primary purpose of a cooling tower is to lower down the temperature levels of the water used in industrial processes and equipment by allowing air and water to come in contact with each other. The process of a cooling tower involves evaporation of small volumes of water making the temperature of the water circulating inside the cooling tower lower than it used to be.

You might be wondering where the warm water came from. As earlier said, this warm water comes from industrial processes and equipment. When the industrial equipment like the air conditioning condensers run, they produce hot water. The primary function of the crossflow cooling tower is to circulate this warm water and then transfer it back again to the industrial process once it cools down.

There are many different types of cooling towers- natural draft cooling tower, cross flow cooling tower, round cooling tower, pultruded FRP cooling tower, and field erected cooling tower, to name a few. However, no matter what type of cooler you have, it is important to make sure that it is properly cleaned and maintained in order for it to function with maximum efficiency. Proper maintenance will also ensure that the quality of the cooling tower stays high and its operating life is kept at a maximum. You can also easily save up at least 15% on electricity costs and at the same time conserve water by making sure that the cooling tower functions well.

On the other side, neglected water coolers would most likely increase energy costs. Not to mention the higher possibilities of damaging the equipment. Repairing a broken cooling tower will not only cost you hundreds, if not thousands, of dollars but it can also affect your day to day industrial processes which can lead to bigger losses.

Speaking of maintenance, there are different proper ways to do it. Here are some of them:

- Schedule regular routine maintenance and make sure you religiously follow the said schedule. However, if you suspect something is off with how the cooling tower works, then order an inspection immediately. This can help you act fast and prevent any problem from happening before it even starts.

- During routine maintenance, one should assess the overall condition of the cooling tower. The inspector should pay attention to out of normal noises and movements of its parts. This is to find potential issues in operating the cooling tower.

- To ensure everyone’s safety, the mechanic or operator should make sure to follow proper procedures in locking out the cooling tower. Also, before starting hands-on work, always make sure to disconnect switches, plugs, and wires attached to the cooling equipment.

- The inspector should check the cooling tower’s strainers to make sure that the equipment is free from excess materials. Also, the debris left on the equipment should be cleaned as often as needed to ensure safe operation.

- Since the cooling tower’s operation focuses on evaporation, the equipment will experience periodic scale deposit buildups. This is caused by the minerals present in the water which most likely exists when there are water treatment issues. This build up will decrease the efficiency and performance of the cooling tower. The scale deposit buildups will likewise quicken the speed of depreciation of the equipment.

The water distribution system of the cooling tower, as well as the dry areas over the fill coil section, should likewise be thoroughly checked by the inspector. This is done to ensure that scale buildup will be avoided, and system capacity will be increased. In case the water distribution system does have dry areas in it, the inspector should check the nozzles if there are cracks and clogs.

Managing the scale deposit buildups frequently during the year will help conserve energy and lower its costs. This will also make sure that the equipment is in its prime at all times during its lifecycle.

- Contaminants like scale, bacteria, algae, mud, and slime may build up inside the cooler’s tubes and can cause partial or total clogs. This may then lead to system breakdowns and low-quality performance. The frequency of maintaining the tubes depends on the water quality and buildup of debris and dirt. It is the nature of the cooling tower to produce these buildups. Since it is unavoidable, it would be very important to constantly keep them on your maintenance checklist. Clearing it regularly will prevent total clogs. Clogging will not only affect the way the cooling tower functions, but it will likewise result in much more expensive costs.

- Another important step in maintaining the cleanliness of the cooling tower is to make sure that the debris and dirt coming from the basin containing the cold water are flushed into the sump strainer or tower drain. This is to preserve the system’s water filtration. Also, this will prevent the dirt from collecting and clogging. You can also install basin sweeper piping. This will serve as an automatic cooling tower maintenance, in addition to the water filtration system.

- Always inspect the water pump. When it comes to working properly, the cooling towers rely greatly on the water pump. If the pumping process is kept at its optimal efficiency, the cooling tower’s performance quality will also increase. This can also save energy costs because a well-maintained pump need not work twice as hard in pumping the water. This makes it easier and quicker for the machine to work. It will not also mess with the useful life of the equipment since it is operating as it is supposed to be.

- The inspector should also check the backup water supply. It is important that the water level is predetermined. To conserve water, the inspector also needs to see to it that there is enough volume of water available. This will also reduce the entrainment of air.

- Make sure that the air can flow properly. By ensuring proper air flow, system breakdowns and low-quality performance will be prevented. Poor airflow may cause the air to cool down very slowly (or even to remain warm) which can disrupt the equipment’s purpose. This may be caused by loose parts, improper component alignments, and lack of machine maintenance. There are a few reasons why the airflow is reduced. One primary reason for reduced airflow is when the fan blades are damaged. You can use a tower vacuum, though, to remove this threat. Always check for debris and dirt within the tower or fill. A biocide may also be added because it can reduce the growth of bacteria and algae in the cooling tower.

- The bleed rate of water should be adjusted accordingly per the local water quality and evaporation rate regulations. This will prevent unnecessary accumulation of solids in the process of recirculating the water.

It is important to focus on the quality of water circulating inside the cooling tower. This is because its quality will decide the rate of scale buildup which if in excess may cause significant system breakdowns. Although it may seem initially costly, investing in an effective water treatment system can help you save more dollars in the long run.

- The inspector should detect and fix any problems concerning tension on the belt. This is to ensure that the belt-drive system is performing at its maximum efficiency.

- The oil level, the oil quality, and the shaft alignment of the gear-drive system should also be routinely checked at a frequent interval. The manufacturer’s recommendations to assure reliable quality performance and great quality services should always be followed and observed.

- Every three months, or quarterly, at a minimum, the fan shaft bearing should be lubricated. This is to maintain maximum efficiency in its operation. It is easy and manageable to install automatic bearing greasers. This may also eliminate the monthly maintenance costs for the fan shaft bearings.

The frequency of maintenance procedures varies depending on various factors like the condition or quality of the water circulating in it as well as the location and environment where the cooling tower operates. The 14 maintenance checklist mentioned above will greatly help you determine possible problems on the cooling tower system, fix diagnosed issues, and prevent equipment failure and quality decline. Regular and proper maintenance can also help extend the useful life of the cooling tower and at the same time increase its residual value during the time of disposal.

By maintaining the cleanliness of your cooling tower, you can save time, money, and energy while having it operate in its maximum efficiency.