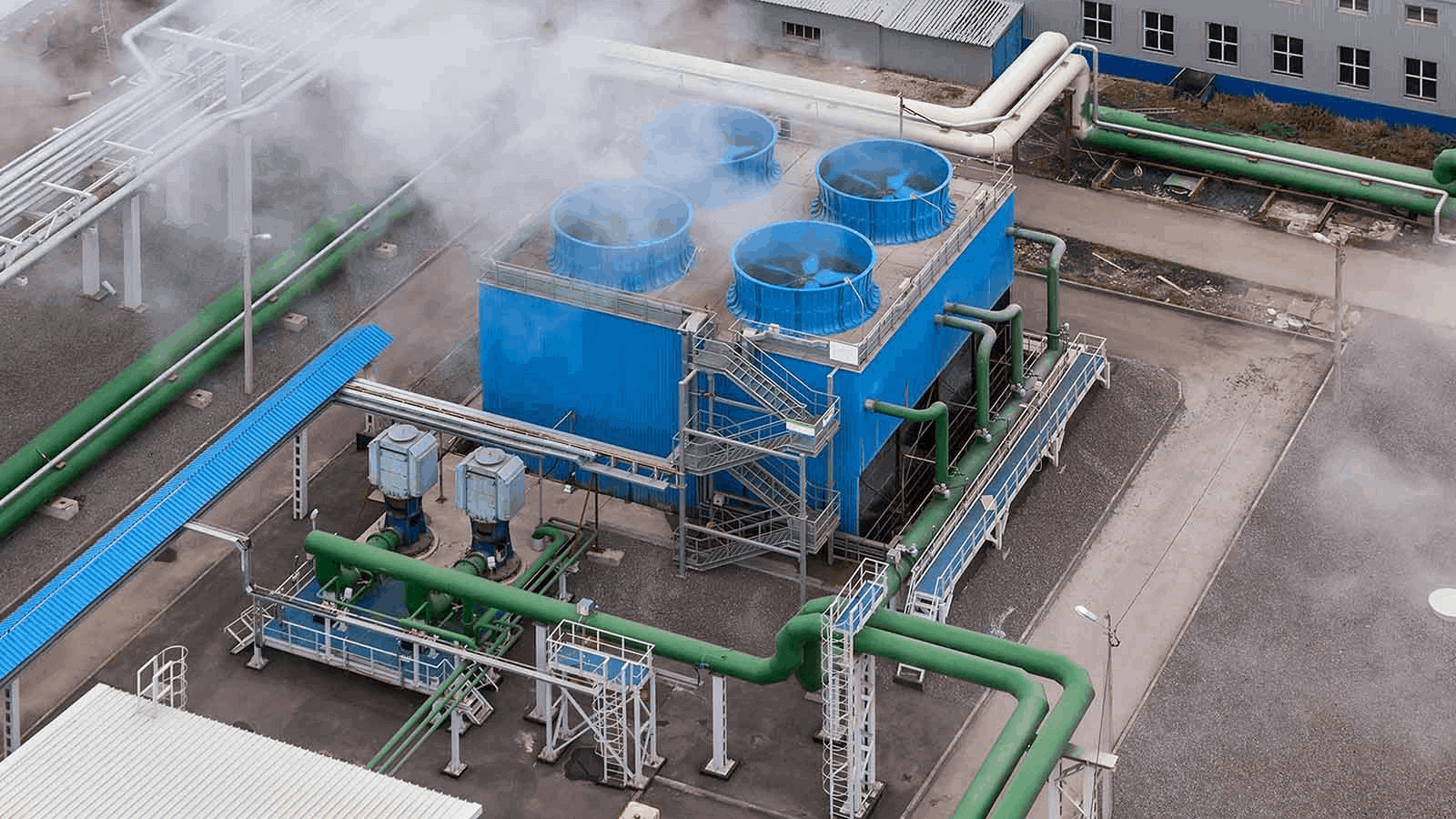

The cooling tower is primarily used to maintain a healthy heat level within a facility. It is a heat rejection device that utilizes the power of water to eliminate excess heat from the facility, thus helping maintain a favorable temperature level. Through this specifically engineered technology, the unwanted heat from the facility is transferred into the atmosphere.

Want to know more about the industrial cooling towers? Below are answers to some of the commonly asked questions about cooling towers.

What is an Industrial cooling tower?

Industrial cooling towers are large, hollow, barrel-shaped machines installed in a building to expel internal heat, and deliver heat-free, ready-to-use water across the building. It also aids in releasing accumulated heat from the water used in machines and air conditioning systems. These towers release the warm air into the environment after removal from the evaporated water stream.

What are the types of industrial cooling towers?

The industrial cooling tower manufacturers in India offer different types of cooling towers. And they are subcategorized into three.

According to Build

- Package Type. This type of cooling system is pre-manufactured and can be bought off-the-shelf. Their function is generally intended for small-scale facilities that do not give off much heat and require only a little heat expulsion.

- Field Erection. These are usually custom-made with respect to the facility’s needs. Usually applied to large-scale industrial facilities such as manufacturing plants, processing plants, etc.

According to Heat Transfer Mechanisms

- Dry Cooling. Uses a heat exchanging device, more like a tube to conduct the heat transfer from the circulating liquid to the air in the atmosphere.

- Wet Cooling. Also known as open circuit towers. It is the most commonly used type of cooling system. Uses the principle of evaporation for water cooling.

- Fluid Cooling. Also known as closed-circuit towers, this kind of cooling system works almost as similarly as wet cooling. The only difference is that the interaction between the cool air and the warm water happens in a coil within the tower, which also works as a filter for the circulating liquid, preventing it from being exposed to the air outside which can contaminate it.

According to Air Flow Generation

- Natural Draft. Built like a hollow cylinder, the shape and structure of a natural draft cooling tower allow the warm air inside the system to freely ascend to the top of the tower and into the cooler air outside.

- Mechanical Draft. Also referred to as Forced Draft. Involves the use of motor fans to provide a constant flow of air through the tower.

- Cross Flow. Airflow and water flow intersect with each other. Air is being blown horizontally while the water flows vertically.

- Counter Flow. Movement of air is opposite to that of the water. The air blows upward while the water is pumped downward. The cooled water is then collected into the fill and redistributed to the facility.

What are the benefits of an industrial cooling tower?

Investing in an industrial water cooling tower is costly. But the long term benefits make it worth the investment, especially for a large-scale industry that employs heavy machines and equipment. These machines heat up with continuous use, and that heat can damage the machines. With the help of cooling towers, heat build-up can be reduced, and maybe even prevented.

Regular treatment by cooling towers can:

- Lengthen the life of machinery.

- Conserve water by lessening consumption.

- Prevent overheating of machines.

- Eliminates the need to continuously dispel heat manually.

How much does an industrial cooling tower cost?

The average price of a cooling tower system typically starts from 50,000 USD and can run as high as 250,000 USD depending on the structure and added features. The price, though, varies per industrial cooling towers manufacturers.

Why let an expert do maintenance and repair services?

Because to put it simply, you just can’t do it yourself. Proper maintenance and repairs are needed to ensure the efficiency of the cooling tower. The maintenance and services of a cooling tower system need technicians with adequate knowledge, expertise, and tools to handle such heavy machinery. You can be guaranteed competent, and dependable services from experts.

What is the importance of regular cooling tower maintenance?

Since cooling towers regulate airflow, either from an outside source or mechanically produced, particles in the air such as dust and bacteria can be caught and built up in the tower that may cause operational problems and reduce its cooling efficiency. Specifically, calcium deposits from the constantly circulating water are unavoidable, that is why it is important to conduct regular tower check-ups and make immediate repairs if necessary to keep operations smooth. This habit will save you from big repair costs in the future.