What is a cooling tower?

Cooling towers are a particular type of heat exchanger that provides water and air to contact each other to reduce the hot water temperature. During the cooling tower performance process, small volumes of water evaporate, decreasing the temperature of the water that’s being circulated throughout the cooling tower.

In summary, the idea of a cooling tower is to cool down water that gets warmed up by industrial equipment and methods. Water comes in the cooling tower hot (from the industrial process) and runs out of the cooling tower cold (back into the industrial practice). Here we see cooling tower functions and inner working of cooling towers for varied applications.

How do Cooling Tower Works?

Hot water is generally caused by air conditioning condensers or other industrial methods. That water is tapped through tubes directly into the cooling tower. Cooling tower outlets are used to spray the water onto the “fill media,” which regulates the water flow and opens the maximum water surface area possible for the best air-water connection.

The water is imperiled to air as it flows entirely in the cooling tower. The air is being extracted by a motor-driven electrical “cooling tower fan.”

When the air and water come collectively, a small volume of water evaporates, forming the action of cooling. The colder water gets tapped back to the process/machine that absorbs radiation or the condenser. It reproduces the loop over and over again to cool down the heated appliances or condensers constantly.

Examples of Cooling Towers

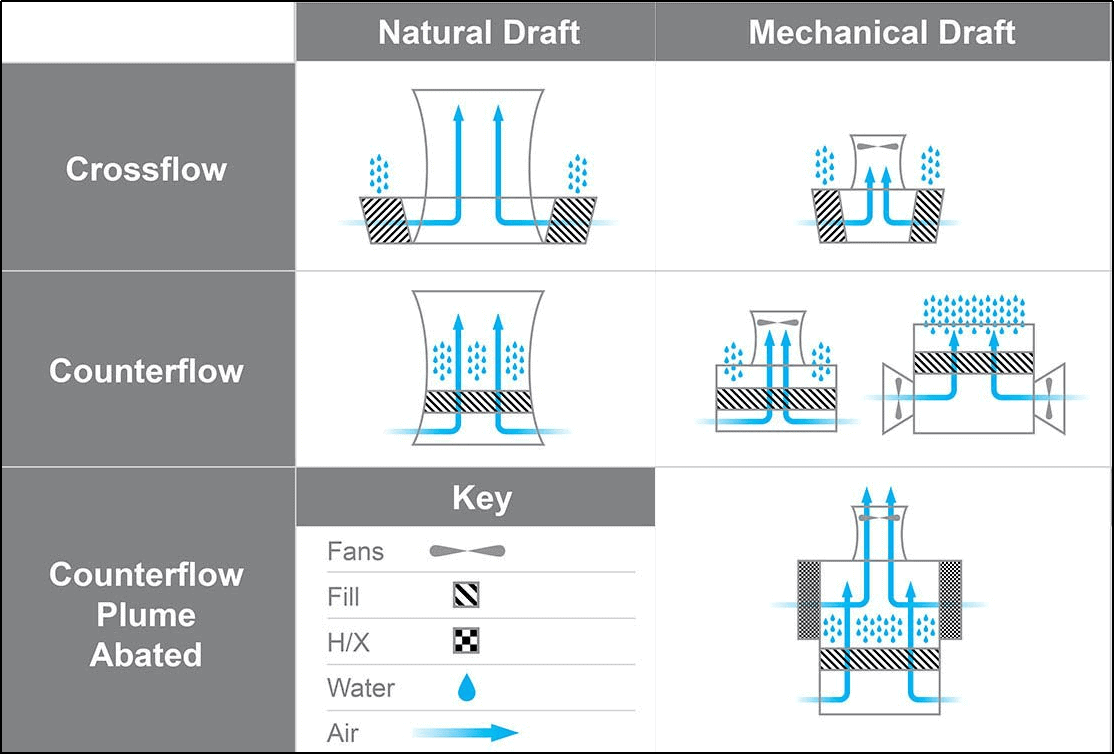

After many years of evolution of this technology, cooling towers are obtainable in different types and sizes. Each of these is suitable in a particular load configuration because it is essential to outline the options available. Despite the different designs, the primary function remains to dissipate heat from a factory system or a method to the air through evaporation. Here are few categorizations.

- Automatic draft cooling tower

- Climatic cooling tower

- Variegated draft cooling tower

- Air flow-characterized cooling tower

- Construction-characterized cooling tower

- Contour defined cooling tower

- Cooling tower based on the process of heat transfer

Each of these could provide several cooling towers. For instance, classifying cooling towers in terms of heat transfer process gives three options: Dry cooling towers, Open circuit cooling towers, and Closed-circuit cooling towers/ fluid cooling towers.

Read Later: Cooling Towers: Applications, Functionality, and Maintenance

These days, cooling towers are in great vogue. Almost every industry needs a cooling tower as a part of its process. These towers are specially designed giant machines that decrease the water temperature when extremely heated. During the industrial revolution, a significant amount of heat is produced.

A cooling tower lowers the heat of the excessively heated water through an air chimney or cooling fans. In simple words, the cooling tower tranquilizes down the extremely heated industrial water.

Moreover, extreme heat inside the industrial machines affects various issues. Sometimes, the entire engine gets damaged due to over-heating of water. The heat is then transferred through the evaporation process.

Fixing a cooling tower in businesses is one of the finest ventures to make. It inhibits the water from pollution and reduces the risks as well. In addition, contaminated or over-heated water heads to scaling or corrosion. And, this makes it compelling to install a cooling tower for adding some more years to the machine.

The cooling tower not only mitigates the over-heated water but also cleans it through various filters. It keeps the water clean, making it useful for other procedures. These towers have many filters that tend the water suitably.

Installing the towers made with top-quality elements is important. The material weighs the most while choosing a cooling tower for your industry. An ideal material inhibits the tower from getting vitiated by corrosion and lessening its life.

Taking help from renowned cooling tower professionals in the area would be highly praised. The experts understand how and where to set up the tower for better functioning. Moreover, the odious cooling tower manufacturers offer premium quality metal in the equipment. Going for the leading certified manufacturers like Towertech would be a wise decision.

The cooling towers offer an exclusive energy-saving feature to intensify the business. A competently cleaned and managed cooling tower will function more efficiently than the corroded one.

Moreover, the towers work effectively when the water is not highly heated—contaminants in the water negatively influence the tower’s effectiveness. And, the cooling tower extracts all the impurities from the water and boosts efficiency.

After smoothing down the overheated water, it is much simpler for the cooling tower to diffuse the water in various containers. The water supply to multiple chambers is generally stopped when the water gets overheated in traditional industries.

For such troubles, the cooling tower works well by reducing the water temperature. You do not have to stop the method when a tower is working in the best efficient way.

One can quickly intensify the business by giving uninterrupted functionality and the same results in countering the damage that might happen to the equipment. Fixing a cooling tower is the most predominant way to save power and increase the composition.

How are cooling towers associated to Atmospheric Vortex Engines?

Cooling towers are generally required to transfer the heat from power plants to other methods and then to the atmosphere. Using the wasted rivulet of heat meant for cooling towers to generate vortex provides the idea of pulling out additional energy by refusing the heat to the colder upper troposphere.

There is always the potential to use wasted heat as additional fuel for atmospheric vortex engines whenever a cooling tower instant or an abundant heat source is available.

At the base of a rustic waterspout, spray from warm seawater transfers tangible and latent heat to the rising air column. An evocative vortex engine mimics this natural heat transfer process using proven technology-adjusted from the cooling tower industry.

However, there is a probability that you will need to make alterations to the tangential air inlet tubes. These changes are required to complete the air rise and create a spinning motion. It would only take a couple of minor alterations to convert cooling towers into atmospheric vortex engines.